Patagonia

Read more about PatagoniaPatagonia

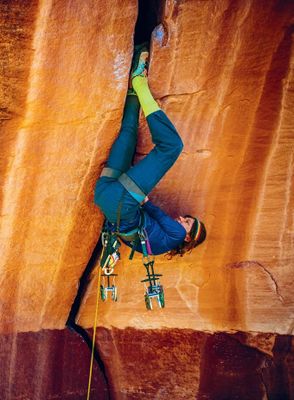

From climbing hooks to innovative outdoor clothing

Patagonia founder Yvon Chouinard discovered his passion for climbing at a young age. As a 14-year-old, the Californian first climbed in the San Fernando Valley, before he later moved to Yosemite for big wall climbing. Since the climbing hooks were made of soft iron and could therefore only be used once, Chouinard decided to produce his own reusable safety hooks. So in 1957, using a forge from the scrap yard, he started to teach himself how to forge and produced his first hooks from the cutting blade of an old combine harvester.

From the small workshop in his parents' backyard in Burbank he moved his production to the Californian coast. With the necessary tools in his car, he was able to alternate between surfing and making climbing hooks here. He sold his hardware from the trunk of his car. As demand grew steadily, his climbing colleague Tom Frost, an aeronautical engineer, joined Chouinard Equipment as a business partner. The collaboration not only enabled the company to switch from manual production to machines, but also resulted in an improvement and revision of the climbing equipment.

The company reached a decisive turning point in 1970, when the growing popularity of climbing caused the rocks to become more and more damaged, especially on the frequently used routes. Therefore Chouinard Equipment, the largest manufacturer of climbing hardware in the USA at that time, decided to withdraw from the climbing hook business. Instead, they relied on aluminum wedges that could be placed in cracks by hand without having to hit them into the rocks.

That same year, after a climbing trip in Scotland, Chouinard brought a rugby shirt to the USA. Thanks to its robust collar, it was also well suited for climbing, as it avoided cutting the material loop at the neck. Soon his climbing friends also wanted a shirt like this, which laid the foundation for the sale of outdoor clothing. Two years later, the range of products ranged from shirts from England, Argentina and New Zealand to rain jackets and biwacksacks from Scotland and woolen gloves from Austria. The clothing line was given a new, own name: Patagonia.

New ideas for the outdoor scene

In the 80s the production of long, warm underwear made of the synthetic fibre polypropylene began. This was the birth of a new layer principle. The base layer was responsible for moisture transport on the skin, the mid layer of polyester served as insulation and the outer layer protected against wind and moisture. With the gradual improvement of the materials, the Capilene® line for underwear and the Synchilla Fleece developed. Two innovations that are still part of the Patagonia range today.

The development of recycled polyester was also innovative. In 1993 Patagonia became the first outdoor company to produce fleece from empty plastic bottles. In the meantime, however, fabric waste and old clothes are also recycled into polyester fibres and used for a wide range of products, from Capilene® functional underwear to weather jackets and board shorts.

High quality for durable products

Outdoor clothing from Patagonia is primarily based on the two principles of simplicity and functionality. The aim is to always produce high-quality products that are functional as well as repairable and hard-wearing. This approach of using materials that last for years or can be recycled makes an important contribution to sustainability, which plays an important role for Patagonia. This is why the company has created the Worn Wear programme. This is intended to encourage people to use Patagonia products for as long as possible and to repair them when necessary, instead of constantly buying new things. What cannot be saved at all, goes back to Patagonia and is recycled.

Active for environmental protection

Ecological values have long been a priority for the brand. Even the decision to stop producing climbing hooks was a first big step towards environmental protection. Patagonia has remained true to this line until today. Already since 1996 only organically grown cotton has been used. The down used to insulate the products is certified according to the Advanced Global Traceable Down Standard and thus guarantees species-appropriate animal husbandry. In addition, recycled down is used for some products. The wool that is processed is also certified according to the Responsible Wool Standard. Furthermore, Patagonia is a bluesign® system partner and the products are Fair Trade Certified.

But the company's ecological commitment also goes beyond its own production. Since 1986 Patagonia has been supporting smaller environmental groups with 10% of its profits every year. In addition to the donations, the manufacturer also implements its own campaigns for environmental protection and regularly holds conferences for environmental activists.

(Photos: Patagonia - Dana Edmunds|Jeremiah Watt|Mikey Schaefer|Julian Rohn|Tim Davis)