Helly Hansen

From linseed oil to waterproof clothing

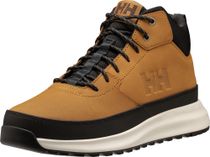

In 1877 Captain Helly Juell Hansen found a way to better protect himself and his sailors from the Norwegian weather: He applied linseed oil to a cotton cloth and created waterproof clothing. The waterproof jackets and trousers produced by the company were a direct success. Since then, Helly Hansen has continued to improve its products and develop new technologies that make the products the perfect companion on the water, in the snow or at work. Today, the range includes not only ski jackets, outdoor jackets, ski pants and outdoor pants, but also functional unerwear, shoes and accessoires such as backpacks and bags.

Developing the technologies

Since the company was founded, Helly Hansen has continually developed its technologies to make its products ideal for all weather conditions. Starting with HellyTech®, which is a waterproof, breathable and windproof outer layer incorporated into the products. This special membrane ensures that water molecules cannot penetrate, but perspiration can be released to the outside.

It is supported by the Lifa® technology, which was developed as early as 1970 and has been continuously improved ever since. This 3-stage moisture management system for baselayers wicks moisture away from the body and ensures that the wearer remains warm and dry. By combining LIFA® technology with Primaloft®, the products are light and comfortable to wear - even during the most strenuous activities.

A temperature regulation system for changing weather and activity levels is also integrated into the products. The so-called H2Flow™ keeps you warm by storing warm air in the air pockets and cools down at the same time when needed through the ventilation zips.

Sustainability along the entire production chain

Because of the brand's strong connection to water, Helly Hansen focuses on the protection and preservation of water bodies in its efforts to achieve sustainability. With the aim of keeping the world's waters as clean as Norwegian fjords, the manufacturer tries to use materials with a smaller footprint and to use processes that require fewer resources and cause less pollution. As the oceans absorb half of the carbon produced, Helly Hansen's goal is to reduce the emissions they emit.

One of Helly Hansen's key priorities is also to prevent chemical spills into the environment and our waters. The use of PFC-free PWR plays a crucial role in this. Helly Hansen works closely with research institutes and chemical suppliers of PFC-free DWR treatments and focuses on ensuring the durability and environmental profile of the substitute. To date, the brand has succeeded in replacing 50% of the PFC treated materials with PFC-free alternatives that have a better environmental profile and still meet high standards.

Helly Hansen also uses 100% RDS certified down. The Responsible Down Standard (RDS) is an independent global standard that recognizes and rewards best practices in the down and feather industry. Its aim is to protect animals and provide global traceability throughout the down industry.

In addition, the manufacturer makes sure that its suppliers are committed to nature conservation and maintain good working conditions. For this reason, they have drawn up a so-called "Code of Conduct", which suppliers must comply with. In addition, most Helly Hansen products are bluesign® certified. The widely recognised and independent bluesign® system acts as a global guiding tool to ensure that the entire production chain is environmentally conscious.

(Photos: Helly Hansen)